Wednesday, November 30, 2016

Tuesday, November 29, 2016

Treated Water, Not for Drinking Purposes

This is a tanker (not seen one of these before) that a builder uses

to transport excess treated STP water from an apartment he manages to a

site where construction is ongoing (one of his own projects). The excess

treated waste water is used for construction. This tells us that he is

confident of his own quality of treated waste water . Many builders

often shy away from using treated waste water for construction as they

do not want to take chances with the quality of construction. Good to

see this responsible action

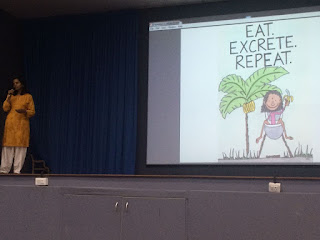

Guest Speaker MS Ramaiah Medical College: "Urbanisation and waste water management"

MS Ramaiah Medical College conducts Interdisciplinary Community Orientation Programme, an innovative

programme organized to sensitize the medical and dental students to the

realities of urban and rural issues. This programme has reached its thirteenth year. Since last

year nursing, pharmacy and physiotherapy students are also participating in

this program.

In this context BIOME Trust was asked to deliver a talk on "Urbanisation and waste water management".

The objectives of this programme are: -

1)

Ensure value education through service to

marginalized groups-people living in villages/slums.

2)

Strengthen skill and attitude input to UG

students to help them serve later as effective doctors and leaders in the

society.

3)

Help the institution to work towards increased

social accountability-in its service, training and research endeavors in

undergraduate curriculum.

4)

Help the students develop appropriate

communication skills.

DATE: 29/11/2016

TIMINGS: 11.15 -12.15pm

VENUE: MSRMC college AUDITORIUM

Retrofit DEWAT At Mr. Sai Kiran’s residence

Overview:

Mr. Sai Kiran approached Biome to help design a system to treat the wastewater discarded from the kitchen. There are two kitchens at 1st and 2nd floor respectively, where meals for 8 members, are prepared routinely. The quantity of kitchen wastewater generated per day is estimated to be 400 litres. The family takes care to use natural washing agents like shikakai and ash. Usage of detergents is minimal.

The generated wastewater flows down the rear of the building and then enters the sewerage system. The existing plumbing is such that a common pipe carries the wastewater stream from both kitchens. In general kitchen wastewater is a good source of nutrient for plants however it needs to be freed from any oil/grease content before usage. So it was required to design a grease-trap cum baffle chamber followed by a aerobic plant-gravel System.

Working Principle:

Stage-I:

a) A treatment system to remove the oil and grease from the kitchen waste. b) Consisting of an oil and grease trap, and a baffle filter. c) The treated water will be rendered free of grease and large solids.

Stage-II:

The semi treated grey water will then be passed through a planted gravel base. The root of the plans supply oxygen to aerobic bacteria present in the water which further breaks down the undesired particles in grey water. After this state water would be clean by almost 80%

Stage-III:

The treated water then goes to a another container to be used for gardening or flushing( if dual plumbing system is set).

Execution:

The project has been implemented by Mr. Babu, he has been associated with all plumbing work in Mr. Sai kiran’s resident. Below are few pictures taken during the implementation and testing phase of the retrofit system.

.

Grease trap

below is the 3 chambered (1 cft. each) grease trap separated by two baffles. This is before covering.

Planted Gravel Filter - The 2nd unit through which the water passes.

Sunday, November 20, 2016

Bangalore's Capacity to Treat its Wastewater

Over the last 60 years, Bangalore has witnessed a huge growth in its ever growing population. The city was home to over 778,977 people in 1951 is currently home to over 11.5 million people in 2016. Rapid Industrialization and urban development in the city has led to a tremendous growth in its population.

This has also meant that the water use has increased and so is the quantum of wastewater produce. The statutory organization Bangalore Water Supply and Sewerage Board (BWSSB) was set up in 1964 under the BWSSB Act whose core functions & responsibilities include

Among other practices followed to treat wastewater, BWSSB has a network of centralized treatment system, where 'Blackwater' (water coming out of the toilets) is transported to Sewage Treatment Plants (STPs) with the help of sewer lines. The city has 14 such facilities to treat wastewater using different technology and several more are proposed to augment the treatment capacity. According to the BWSSB estimates, the quantum of the sewage generated was 985 MLD in the year 2011, which would increase to 1320 MLD by the year 2021.

Sl no

|

Location

|

Capacity

in MLD

|

Treatment

Facility

|

1

|

Vrishabhavathi

Valley

|

180

|

Secondary

–Trickling filters

|

2

|

K &

C Valley I

|

248

|

Secondary:

Activated sludge process

|

3

|

Hebbal

Valley

|

60

|

Secondary:

Activated sludge process

|

4

|

Madivala

|

4

|

Secondary:

UASB + oxidation ponds+ constructed wetlands

|

5

|

Kempambudhi

|

1

|

Secondary:

extended Aeration

|

6

|

Yelahanka

|

10

|

Activated

sludge process + filtration+ chlorination (Tertiary)

|

7

|

Mylasandra

|

75

|

Secondary

–Extended aeration

|

8

|

Nagasandra

|

20

|

Secondary

-Extended aeration

|

9

|

Jakkur

|

10

|

Secondary

–UASB +Extended aeration

|

10

|

K. R.

Puram

|

20

|

Secondary

–UASB +Extended aeration

|

11

|

Kadabeesanahalli

|

50

|

Secondary-Extended

aeration

|

12

|

Rajacanal

|

40

|

Secondary-Extended

aeration

|

13

|

Cubbon

Park

|

1.5

|

Membrane

|

14

|

Lalbagh

|

1.5

|

Extended

Aeration + Plate Settlers + UV disinfection

|

Total

Existing Treatment Capacity

|

721

|

List of the Existing Sewage Treatment Plants in Bangalore with their respective capacity.

Did you know which is the nearest STP from your location? You can know it with the help of a click.

I have marked the following STPs on a map, which would help you locate the nearest STP. You can click on the link below to see the map.

https://fusiontables.google.com/embedviz?q=select+col2+from+1CT2LtffXi5GHTDIHaYdypjCi6s6VJGWWzsbaDoNs&viz=MAP&h=false&lat=13.000456089209473&lng=77.6922489318847&t=1&z=11&l=col2&y=5&tmplt=6&hml=TWO_COL_LAT_LNG

https://fusiontables.google.com/embedviz?q=select+col2+from+1CT2LtffXi5GHTDIHaYdypjCi6s6VJGWWzsbaDoNs&viz=MAP&h=false&lat=13.000456089209473&lng=77.6922489318847&t=1&z=11&l=col2&y=5&tmplt=6&hml=TWO_COL_LAT_LNG

It was easy to locate some STPs with the exact coordinates, but there are a few others which are marked based on the name of region. Therefore, if you have the exact coordinates for some STPs, then kindly share with us. This will help us to improve the details on the map.

Apart from this, what are other layer of information you want us to highlight in the map? Do let us know.

References

http://www.indiaonlinepages.com/population/bangalore-population.html

V.C Kumar, Potential of STP's in Bangalore, Executive Engineer, BWSSB

http://www.indiaonlinepages.com/population/bangalore-population.html

V.C Kumar, Potential of STP's in Bangalore, Executive Engineer, BWSSB

Saturday, November 19, 2016

Seeing is learning: A visit to Agastya foundation science lab in Bettadasanapura

Time and again teachers and principals at high school have revealed

to us that children especially in government schools fail to understand some

basic concepts taught at primary school level. The reasons are manifold and

there are existing evidences to confirm this. What seems to be working or at

least getting children enthused about studies, is the activity based learning.

We saw in my last post that how delighted the kids were when

movies, videos were projected on big screen which helped them understand some

concepts about water cycle. Couple of days back, we made a visit to Agastya International Foundation’s Science

Lab in Bettadasanapura near Electronic city, Bengaluru. The visit was

facilitated by Mr. Nandeesh from ELCIA

Trust. ELCIA Trust has adopted 19 government schools around Electronic

City. To facilitate better learning for these government school students ELCIA

invited Agastya foundation to set up a science lab. One of the schools’ campus

was identified for setting up this lab.

The science lab is open throughout the day from 10.30 am to

3.30 pm. Two tutors from Agastya conduct daily two sessions for the students of

these 19 government schools. The batches are decided, fixed with consent from

school, the concepts explained as per the standard/grade the students are

studying in. The lab has conceptual models for explaining basics on biology,

chemistry, physics, geography, etc. The models are developed as per the

syllabus for each grade and hence relevant for students to learn and

understand.

The tutor from the lab, Mr. Sunil, said that “if you explain

the concepts in a lighter vein and show children the working principle, then

the difficult concepts become simple and easy to comprehend”. We at Biome hope

to learn from these initiatives and develop some conceptual models for

explaining concepts related to water.

Saturday, November 12, 2016

A day with Government school children: Speaking on water issues

We have been engaging with couple of government schools in

and around Bengaluru International Airport for the past couple of months. The

engagement is not limited to hard infrastructure components like rainwater

harvesting but also involves lot of soft components to create ownership,

handholding of the system for teachers and students.

It was one of such sessions with Kannur Primary School and

Kadusonnapanahalli High School. In Kannur, the students were from 1st

to 5th standard whereas in Kadusonnapanahalli students of 10th

standard attended the session. The interaction focused on water cycle, facts

about water, water scarcity, and briefly touched upon water scarcity and

necessity of conservation. The session was mix of sharing videos, talking and

interaction.

The smiles on the faces

of small kids, especially the primary school kids, makes your day. Principal Ma’m

of Kannur Primary School, Ms. Manjula said, “Students are always happy to see something

on big screen. It just cheers them up and a good way of teaching them.” While

we had videos to be shown, we couldn’t get a video projector on time before the

session. Kadusonnapanahalli school had it in house so we weren’t worried about

it. But Kannur we weren’t sure. We reached the school and started talking to

the Principal Ma’m about showing the videos and she delightfully says, “We have

a projector.” She showed the projector and the set up and it was the most

amazing thing that I could have seen. The school is selected for ‘Meghshala’

project which uses audio-visual methods as learning aids.

The whole set up comes with a small portable projector, a Wi-Fi dongle, tripod, portable speaker, and a tab with in-built lesson plans. Projector also has a USB port and USB chord to connect the speakers. This is such a useful thing for the schools to have. Though the teacher still doesn’t feel comfortable with using the this, and sometimes struggles with using USB, this learning method has certainly caught the students’ attention. Kudos to the team. If you have some information about such projectors, price, we would like to explore more.

Kadusonnapanahalli school had its own set up and multiple

options to project. A big TV screen connected to a DVD player which somehow

couldn’t be used that day. A wall mounted projector wasn’t working. Finally, we

used portable solar powered projector donated to the school by Rotary.

We sourced videos available freely on the web platform. We especially

thought the video by Agastya International foundation on Water cycle was very

useful. For one, it was in Kannada so students could follow it and second, it

was activity based so student understood the concept.

Thursday, November 10, 2016

Kaveri 101

- See the map to Identify the 4 major reservoirs in Karnataka : Hemavathy, Harangi, KRS and Kabini. Inflows and Outflows to all 4 reservoirs are monitored and known and this forms the basis of all calculations

- The river flows into TN and at Biligundlu there is a measuring station that tells you how much water flows into TN from Karnataka

- The water that flows into the river downstream of KRS and Kabini is measured at Biligundlu , is expected to flow in from about 22,000sqm and in an average year can contribute about 80TMC.

- About 740TMC is the total water that is expected to flow into the river (from all states)

- Of this the following allocations have been made (the states are entitled to the following volumes of water

- Kerala: 30TMC

- Karnataka: 270TMC

- TN : 419TMC

- The total inflows into the river from Karnataka is 462TMC. Of the 462 TMC, Karnataka can keep 270TMC for itself and has to give TN 192 TMC (this is measured at Biligundlu). For the purpose of this post, we assume that the basis of this split is agreed upon (270 keep, 192 give)

- So if you see the only real numbers that matter are, irrespective of rainfall across the catchment, based on the total inflows in Karnataka,What Karnataka keeps 270----------------------------- = ------What Karnataka gives TN 192

Hence

if the total inflows in Karnataka was 100TMC, Karnataka can keep

58.44 TMC and send to TN 41.56TMC. Hence one would not need to base

it on the % rainfall deficit/surplus – but on actual inflows. The

inflows can be measured on a daily basis, the corresponding keep and

give numbers calculated and released at some predetermined/useful

frequency. It seems fair ? And simple ?

Now

the inflows to/from all reservoirs are known , the additional inflow

from 22,000sqm at Biligundlu is also known. This should make the

actual sharing numbers even in a deficit year – a reasonable and

clear calculation

Thanks

to zenrainman's FB post on the same topic for a slightly more

elaborate description,

And

whats TMC ? That for another post :)

Wednesday, November 9, 2016

Do lakes actually recharge ground water ? and by how much ?

|

| Well with water : Near Jakkur Lake |

A question we often get asked as rainwater harvesters is, is there

any point in building a recharge structure adjacent to a lake ? Does

the lake not recharge ground water ? Will the recharge

structure/well make any difference ? This is a very pertinent

question and I can write on what we have seen and learnt - from experience

Very often you do see old open wells adjacent to lakes. The well used

to be the place from where people drew the water for use. The water

level in the lake and the water level in the well would more or less

be in sync. That seems to indicate that water from the lake would

seep out into ground and then into the well. So yes – the lake did

send water into the ground which you could withdraw from the well.

This is still true in many cases – when the lakes fill up, the

wells fill up too. Eg Jakkur Lake

However over a period of time as the lake starts to silt up, the

recharge rate reduces and hence the relationship between the water

levels in the well and lake might also reduce.

|

| New well with water : West of KKHalli Lake |

eg. Kaikondrahalli Lake has an old open well about 40ft deep to its

East that is dry. Three new 15ft deep wells have been dug in the school

to the West of the lake. All the wells have water. However these

wells are being recharged with rainwater too. Why does the East Well

not have water ? Has the well silted up and hence there is no

percolation from the lake to the well ? There is a borewell at the

bottom of the open well. Has the pumping out of water from the deeper

regions emptied out the shallow aquifer ? How come the 3 new school wells have water ? Is it the artificial ground

water recharge and not the lake that is feeding the shallow open

wells in the school ? Its hard to say.

However, one thing that can be said for certain, the lakes dont seem

to be having an obvious/hard to miss positive effect on deep

borewells in the vicinity. Deep Borewells around the lake continue to

dry up or yield less

|

| Dry OLD well: East of KKHalli Lake |

Tuesday, November 8, 2016

Do deeper borewells actually yield more water ? Do we get more water as we dig deeper ?

Having worked with,

seen and spoken to numerous borewell owners, it is apparent that the

borewells that yield well; say about more than 60,000 litres of water

per day (that are used by layouts, tanker operators, industries etc)

are those that are shallower than 600ft. Its not the 1000+ft

borewells that yield copious amounts of water. Even if it is a

1000+ft borewell that is yielding a lot of water, a camera inspection

will reveal that actually its the shallower cracks that yield more

water. Take a look at the attached picture to somewhat make sense of

Bangalore's geology and to see how water comes into a borewell. It

does seem more UNLIKELY for water to be available at greater depths

The general

perception is that deeper borewells yield more and hence people dig

deeper. But the contrary is true. In fact as you dig deeper than

600ft the number of naturally occurring cracks in the rock formations

reduce and hence the water availability also reduces. A deep borewell

might be able to provide lifeline water to a home of about 500litres

per day but very unlikely that it is a 100,000 litres per day

borewell. Its the shallower borewells that yield more water.

Would like to hear

and understand from people who have deep (1000+ ft)borewells that

yield more than 60,000 litres per day

Subscribe to:

Posts (Atom)